Tired of inaccuracies in weighing heavy loads?

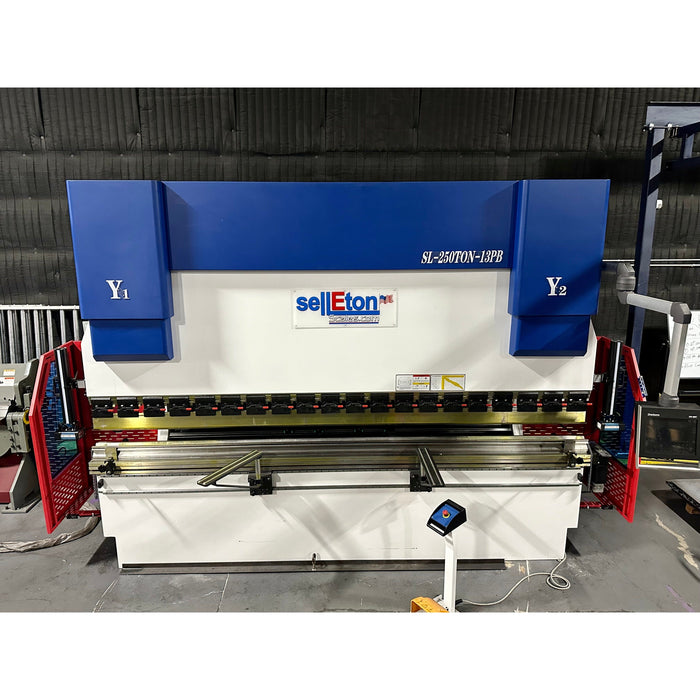

The SellEton SL-250-TON-13PB offers a revolutionary solution to enhance precision in heavy-duty truck and vehicle weighing. Perfect for industries requiring exact load measurements, this sheet metal bending and forming machine integrates cutting-edge technology to ensure accuracy and efficiency in your operations.

Key Benefits:

- Compliance with EU Standards: Designed to meet the latest streamlined standards, ensuring top-tier performance and safety.

- Robust Construction: The unified welding and tempering process, followed by shot blasting and anti-rust coating, guarantees outstanding durability and corrosion resistance.

- Advanced Precision: Utilizes a high-end imported CNC machining center, ensuring exact alignment and perfect perpendicularity for impeccable accuracy.

- Dual-Axis Control: This machine features a sophisticated controller that synchronizes the operation of the Y1 and Y2 axes, enhancing its efficiency and effectiveness.

- Energy Efficient: The servo main motor reduces energy consumption by up to 60%, significantly lowering operational costs.

- Quiet Operation: Operates at about 25 decibels, making it one of the quietest machines in its class, suitable for noise-sensitive environments.

- Temperature Stability: Maintains stable oil temperatures to extend the hydraulic system’s lifespan and performance reliability.

Specifications of the SellEton SL-250-Ton-13PB Bending Machine

- Model: SL-250Ton-13PB

- Bending Force: 2500 KN

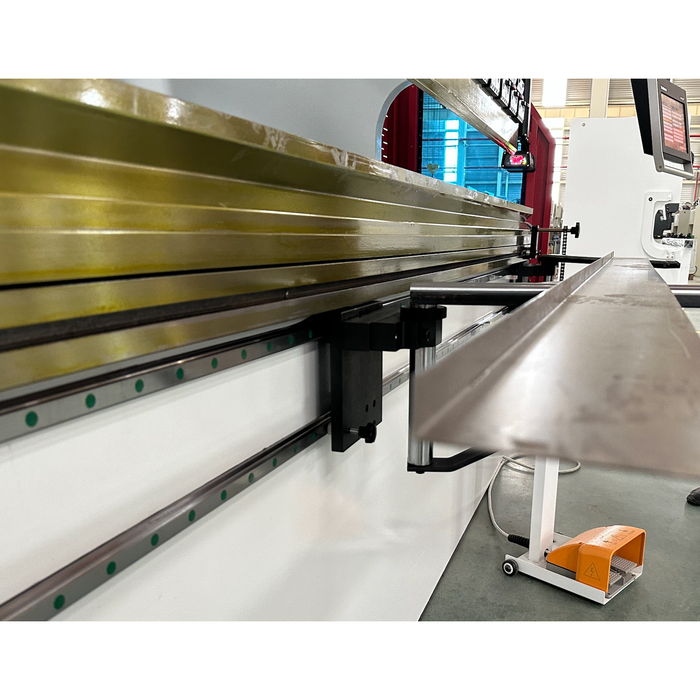

- Bending Length: 4000 mm / 157.48 inches

- Bending Thickness: Mild Steel: 8 mm / 0.315 inches, Stainless Steel: 4 mm / 0.157 inches

- Upright Distance: 3100 mm / 122.05 inches

- Throat Depth: 450 mm / 17.72 inches

- Stroke: 250 mm / 9.84 inches

- Open Height: 540 mm / 21.26 inches

- Fast Speed: 100 mm / 3.94 inches

- Working Speed: 8.5 mm / 0.335 inches

- Return Speed: 100 mm / 3.94 inches

- Slider Repeat Accuracy: ±0.03 mm / ±0.00118 inches

- Slider Positioning Accuracy: ±0.03 mm / ±0.00118 inches

- Repeat Positioning Accuracy of Backgauge: ±0.05 mm / ±0.00197 inches

- Workpiece Straightness: 0.5 mm/m / 0.01969 inches per 39.37 inches

- Bending Angle Error: <±0.5°

- Grating Ruler Resolution: 0.005 mm / 0.000197 inches

- Hydraulic Oil Standard: #46 Antiwear hydraulic oil

- Oil Tank Capacity: 440 L

- Main Motor: 22 Kw

- Weight: 19 Tons

- Overall Dimensions: 15' x 7' x 10'

- Power Supply: 480V/60HZ/3PH (customizable)

Components of the SellEton SL-250-TON-13PB Machine

- Controller: DA58T from the Netherlands

- Backgauge Axis: 4+1 (Y1, Y2, X, R+V)

- Hydraulic Valve: HAWE from Germany

- Hydraulic Gear Pump: HAWE from Germany

- Grating Ruler: Fagor from Spain / Givi from Italy

- Main Motor: Normal Type, Siemens from Germany

- Electrical Components: Schneider from France

- Crowning: Motorized Crowning

- Ball Screw and Linear Guide: PMI/PYM from Taiwan

- Servo Motor / Servo Drive: Estun

- Tubing Connector: JS/EMB from Germany

- Clamps: Fast clamp

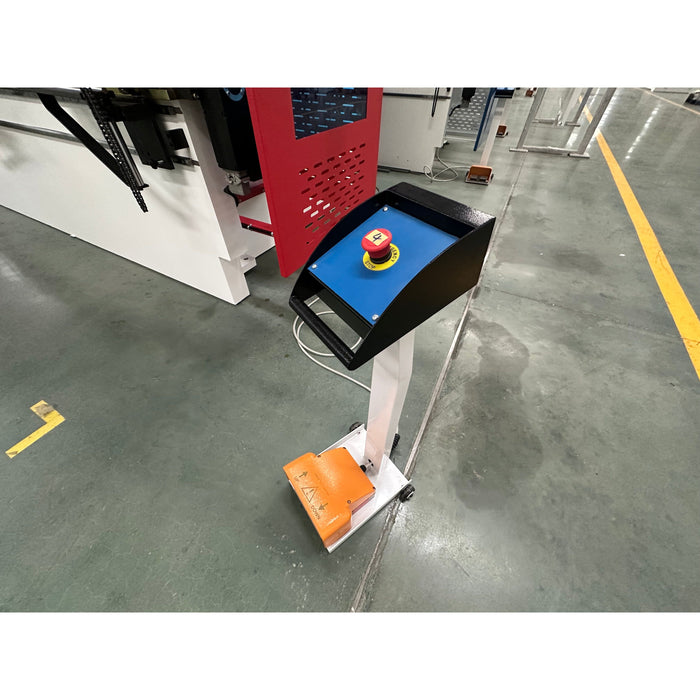

- Pedal Switch: Roller Type from China

- Front Protection: Left & Right Guard

- Rear Protection: Fully Enclosed Rear Guard

By choosing the SellEton SL-250-TON-13PB, you not only invest in a high-quality and certified truck weight scale, but you also ensure that every measure is accurate, every bend is precise, and every operation runs smoothly. Feel confident and empowered as you elevate the standards of your industrial processes, ensuring that your operations are efficient, your results are reliable, and your industry standards are exceeded. This machine isn't just a purchase; it's a pivotal step towards optimizing the productivity and profitability of your business.

Please contact our sales team for more information or to discuss your specific requirements. We're here to help you find the perfect weighing solution for your industrial needs.

Free Shipping: Available across 48 continental USA. Extra charges may apply for residential, farm, or rural areas.

Express Shipping: Overnight and faster shipping options available at additional costs. Quotes obtainable via email.

Delivery Time: Typically 5 to 7 business days, varying by location and external conditions.

Tracking Information: Provided via email upon shipment. Accessible through account login. Additional information available upon request.

Return Policy: 15-day return period for unused, original condition products. A 25% restocking fee applies. Buyer covers original and return shipping costs.

Customer Support: Contact at (844)-735-5386 or info@selletonscales.com for queries or concerns about shipping.