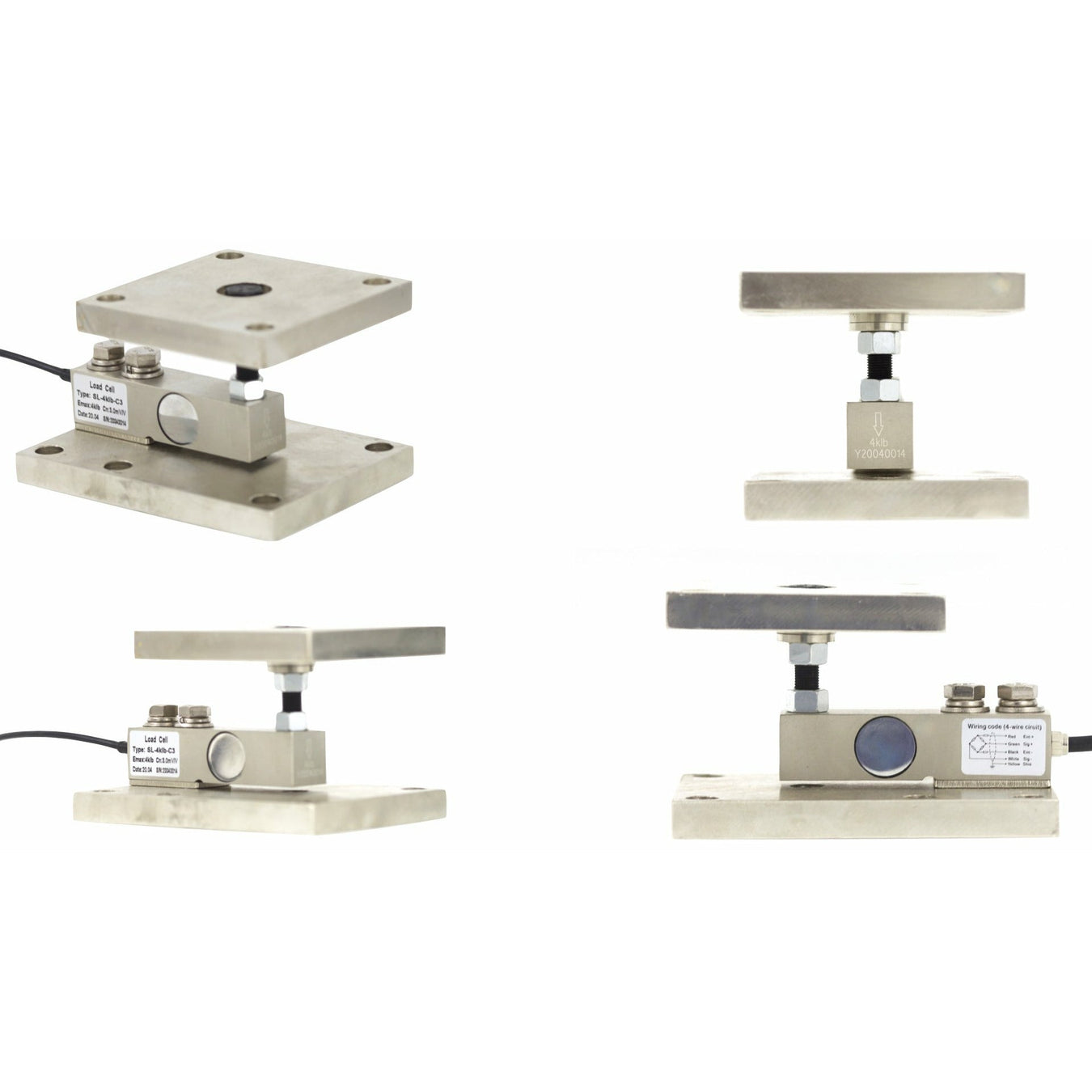

Load cells are typically used with platform weighing scales. With load cell scales, digital weighing can be more accurate, reliable, and precise. The size and types of load cells used vary depending on the size and mass of the item being weighed. Load cells can be used in a wide range of applications in numerous industries.

The most common type of load cell are those that use strain gauges. With the help of these gauges, more accurate weighing figures are established.

If your company is looking for load cell kits for your weighing needs, SellEton offers a range of durable, high-quality, accurate, and reliable load cells. To make sure your load cell kit matches your equipment and the needs of your industry, don’t hesitate to give our team a call. We can recommend the most applicable load cell kits for you.

Get in touch with us through phone at (844)-735-5386 or send us an email at info@selletonscales.com.